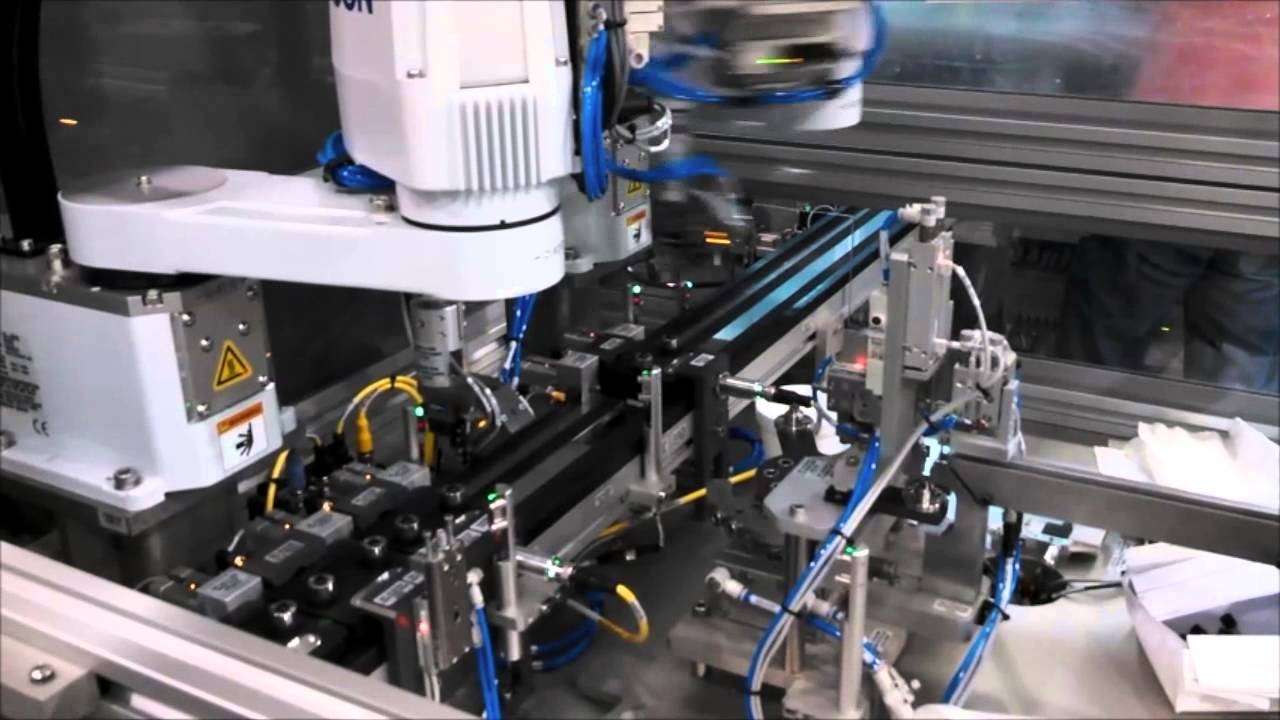

Robots have been a part of industrial production since the 60’s and have managed to last this long due to their speed and accuracy. Automation in production lines is one of the best things that have ever happened to manufacturing industries because it helped to increase productivity along the lines tremendously. Production line robots are also known as assembly robots, and they have numerous advantages and just a few drawbacks.

Control of a production line

A production line is usually controlled manually by a supervisor who is tasked with regulating things such as the speed of the robot or the direction in which it is moving. This is usually done by the use of buttons or a manual joystick. Configuration and reconfiguration of robots is easy, and so they can be reset to do many diverse tasks which in turn makes them really valuable to manufacturing companies that produce different products.

The business aspect

Business wise, robots have a higher Return On Investment (ROI) along the production line as they require minimal maintenance and low supervision compared to humans. This makes them the ideal investment for manufacturers who have to produce items in bulk because the cost of production automatically goes low.Faster production ensures speedy delivery of goods to customers and this attracts more traffic towards the business. This means that a business is more likely to experience increased customer growth after incorporating robots in their assembly lines.

Reduction of waste

Due to its accuracy,a robot reduces waste significantly on an automated production line thus boosting profits. When work on a production line is not done accurately, a lot of product ends up being wasted and this generally contributes to the outcome, and the profits either being maximum or average. Production lines that have incorporated automation also benefit from improved work quality and reliability, due to the accurate nature of robots that enables them to repeat a process over and over while still maintaining highstandards of quality.

Automation also reduces human footprint since robots save up floor space, and this helps in maximum utilization of the work space. Because of this, companies can be able to reduce their rental costs.

Challenges of production line automation

For starters, the initial capital investment for robotic automation in a production line is huge and most businesses may find it expensive. Training of employees to adopt the new equipment may take time and can bare a financial toll on a company aiming to automate their production line using robots.

Secondly, the Return on Investment of a company can be affected if itdoes not realize the profits that were expected from purchasing robots. As a matter of fact, if the money earned does not match and go beyond what was spent, the company might end up operating at a loss.

Lastly, system malfunctions are a possibility with robotic automation and when they happen, it could result to a lag in production or even a complete halt of the production process, and this may result to losses. On the other hand, fixing the problem can also prove to be another financial hurdle because they tend to be costly.

Automation versus human workforce

Generally, automation leads to loss of employment along production lines as humans are replaced by robots. And even though automation signifies growth in a manufacturing company, it also has economical and social impacts on communities that were relying on the employment opportunities. In addition, some products may require the human touch for one reason or the other, but this cannot be done by robots regardless of how advanced they are.

Further more, Robots along production lines cannot deal with unexpected occurences as they are only programmed to perform specific tasks, and even if the robot has Artificial Intelligence, it will never have the ability to generate its own thoughts the way that a human can.

Ultimately however, automation is very advantageous to a production line when approached objectively. And when all is said and done, the pros outweigh the cons.